The Breeding Stock Professionals

Give us a call: (775) 463-2677

Want to feed your cattle at Snyder's?

Preparing your cattle to be fed at Snyder's just got easier!

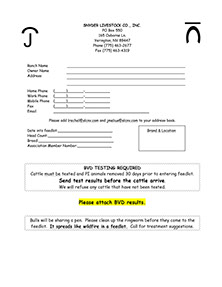

Just download or print the Feedlot Entry Form. Send your completed forms via email (jmelius@slcnv.com), snail mail, or put it on the truck with your cattle. Schedule the day and time you will ship your cattle by clicking on our easy scheduling button. Expect to hear from us soon to confirm the details. Make sure to include vaccination details with your paperwork.

We are looking forward to working with you.

BVD Testing

17 years ago, we initiated mandatory BVD testing for all animals entering the feedlot. We launched the program with a bull sale seminar in which Dr. Bill Kvasnicka and Dr. Julia Ridpath outlined the creation of PI animals and how removing those from the herd would improve reproductive performance, herd health, and disease resistance. They were adamant that, to see these improvements, calves needed to be tested and PI animals removed from the herd before breeding season (at branding time.) We have offered a discount for herds in which this protocol is followed. That discount more than covers the cost of testing if cattle are fed for over 90 days. In spite of that, very few of our customers are testing at branding.

In the first few years, we identified quite a few BVD PI positive animals, both in seedstock herds and commercial herds. In the last several years, that number has decreased to nearly zero.

Many Snyder customers feel that the testing is an unnecessary expense. Because we find so few PI animals and because of very justified resistance from you to test the animals, we are eliminating the BVD testing requirement.

For seedstock producers, selling PI tested bulls has become an industry norm. Introduction of a BVD PI positive bull into a commercial herd could have major negative consequences for that customer. Many consignment and bull test sales, including Redbluff, Fallon, and Bulls for the 21st Century, require testing. I strongly suggest that you continue to test your bull calves before bringing them to the feedlot. We will also phase out our BVD discounts. For calves that are already in the feedlot or have been tested on or before May 1, 2020 to meet our entry requirements, we will continue to honor the BVD discounts as in the past. Moving forward, we will require BVD PI testing only on the bulls consigned to our sale.

We have been testing cattle for feed efficiency since 2006.

After much rain and snow... the straw was very welcome.

No more looking for a dry spot to lay down.

We may not get them to move again.

Looking very comfort-a-bull.

A Brief History

Snyder Feedlot was built in 1969 and is managed by Lucy Rechel. The 5000 head capacity facility has three distinct functions. In fall and winter, Snyder backgrounds light calves. The small feedlot and Lucy’s attention to detail is an ideal place to get bawling calves acclimated to feedlot life before they transition to the larger finishing feedlots.

Bull development is the second key component of Snyder’s feedlot operation. Many California and Nevada seedstock producers trust Lucy to develop their bulls from weaner calves to yearlings or long yearlings ready to be sold to commercial cattlemen. Data collection is a major component of bull development. Monthly individual weights, yearling ultrasound, individual feed efficiency, and other data points are all measured at Snyder feedlot. Services such as semen testing, ultrasounding, grooming, and hoof trimming are all available to customers and are done by outside professionals. The annual bull test and sale was a natural addition to the bull development aspect of the business.

Snyders also develop and AI heifers. Data is collected as it is with the bulls. Additionally, we artificially inseminate the heifers per owner request. Most heifers leave the feedlot when they are 14-15 months of age to rejoin their herdmates on pastures or native feed.

Snyders have incorporated technology in their feeding operation as they have in farming. Lucy installed one of the first privately owned GrowSafe® systems in the Western United States. This Canadian made equipment measures individual intake, allowing genetic selection for feed efficient animals. An integrated computer system tracks everything from vaccinations and medications to feed events on the cattle in the yard.

Low stress handling is used in all cattle handling work. Every employee in the feedlot maintains a current BQA certification. A micro machine allows inclusion of special ingredients at a very accurate level to target specific animal needs.

Lucy takes a personal interest in the health and well being of every single animal in the lot. She is more likely to be found cleaning a water trough or processing cattle at the chute than in her office.